Southern Steel QLD continues to lead the way in Queensland’s structural steel processing. Our investment in cutting-edge steel processing technology delivers flawless solutions, allowing you to do things your way. We aim to optimise your fabrication process, saving you time and money and allowing you to win more by doing less.

Steel distribution & processing

for Queensland

Steel Processing

Coping

Cutting-edge steel coping technology allows you to do things your way.

The HGG RPC 1200 coping robot offers the most advanced coping technology. Southern Steel QLD’s investment ensures our capability to cut a variety of welded and bolted connections, including single and double weld preps and rat holes.

Our qualified team creates smooth cuts that minimise rework, precisely etches part locations and performs intricate cuts accurately, improving fitting and welding efficiencies.

Steel Cutting and Drilling

We cut and drill long products to specification, including plasma and oxy cutting, mitre, single, pack cutting, drilling, punching, and more on all ferrous materials, including Q&T plate. Our arsenal of machinery and expert operators allows us to work with you to deliver your steel professionally processed when needed.

Our customised cutting and drilling capability ensures we deliver cut steel to your specifications within 1mm tolerance and coping, notching and mitre beams up to 20m.

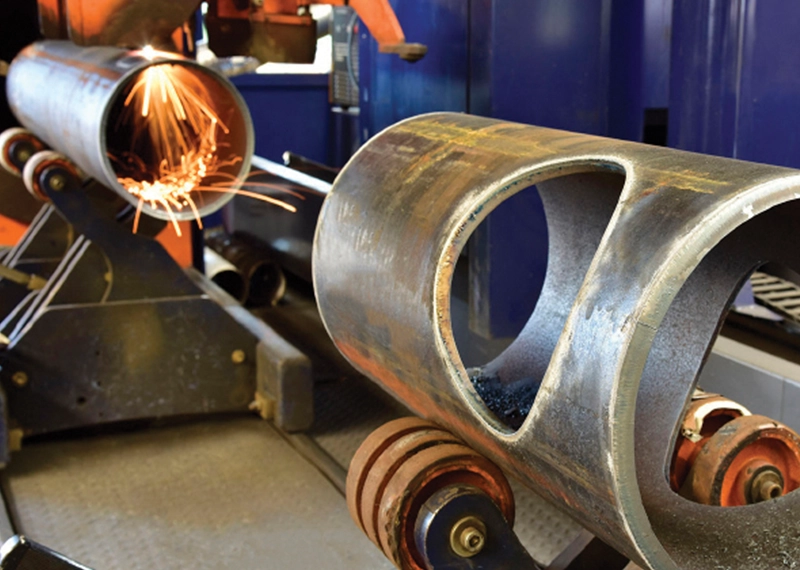

Pipe Profiling

We place a high value on your time so are constantly looking for ways we can simplify your processes to help make you more economical.

The TPC 1000 pipe profiling machine is advanced technology. In a fully automatic CNC-controlled operation, we import CAD files directly to ensure the most intricate work is processed precisely.

Customers eliminate the risk of incorrectly cutting and marking out hard-to-source material using our pipe profiling capabilities.

Laser Cutting – Pipe & Sections

Southern Steel QLD specialises in laser cutting pipe and sections utilising the advanced BLM LT8.20 laser for unparalleled precision.

The BLM LT8.20 laser is a cutting-edge laser tube processing system designed to handle a diverse range of materials and geometries, providing a versatile solution for the most challenging projects. The machine’s advanced laser cutting capabilities allow for intricate designs and complex shapes, ensuring customers can accurately bring their creative visions to life.

Laser Cutting – Flat Products

We’ve invested in the most advanced laser cutting technology – the Trumpf Trulaser 1030 – to ensure each part is meticulously crafted with pinpoint accuracy, eliminating costly rework and ensuring superior quality.

The Trumpf Trulaser 1030 cuts a wide range of thicknesses from 1-25mm and is capable of cutting thin sheets of stainless steel and mild steel along with galvanised sheet metal, aluminium, laminated stainless steel and non-ferrous brass and copper.

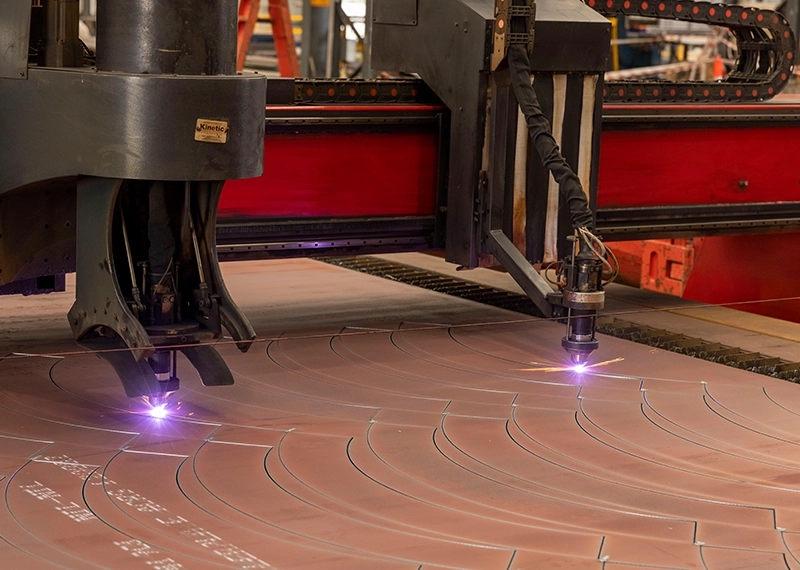

Plate Processing

Southern Steel QLD has invested in advanced steel plate processing capabilities including plasma, laser and oxy cutting. The latest steel cutting technology coupled with our expertise and experienced operators ensure our steel processing is of the highest standard.

Our oversized cutting beds allow us to process using the largest feed plate and our processing services includes bevelling, drilling, countersinking and tapping.